China Truck International Limited supplies EGR coolers for diesel vehicles through long-term cooperation with qualified manufacturing partners.

Our focus is on stable mass production, manufacturing consistency, and joint development for global distributors and brand owners.

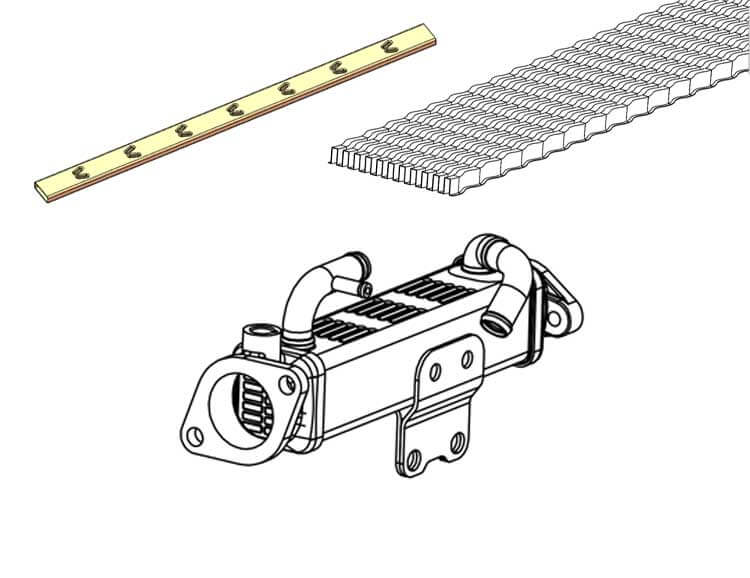

KYD-LQ-08-A

KYD-LQ-08-A KYD-LQ-08-B

KYD-LQ-08-B KYD-LQ-17

KYD-LQ-17 KYD-LQ-15

KYD-LQ-15 KYD-LQ-21

KYD-LQ-21 KYD-LQ-21B

KYD-LQ-21B KYD-LQ-22

KYD-LQ-22 KYD-LQ-22-B

KYD-LQ-22-B KYD-LQ-26

KYD-LQ-26 KYD-LQ-04

KYD-LQ-04 KYD-LQ-31

KYD-LQ-31 KYD-LQ-44

KYD-LQ-44 KYD-LQ-28

KYD-LQ-28 KYD-LQ-29

KYD-LQ-29 KYD-LQ-47-A

KYD-LQ-47-A KYD-LQ-47-B

KYD-LQ-47-B KYD-LQ-30

KYD-LQ-30 KYD-LQ-43

KYD-LQ-43